Features of RISO TECHNOLOGIES' Inkjet Heads

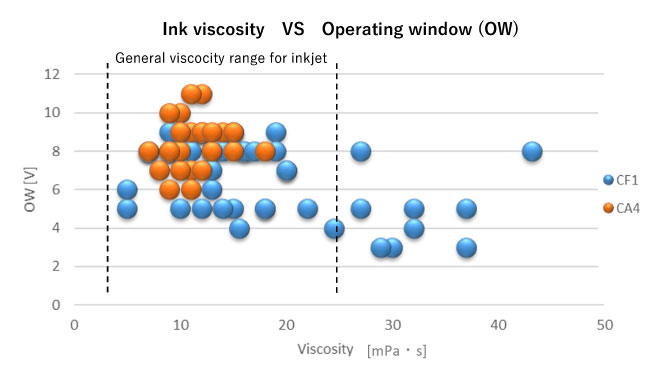

1. High-viscosity Ink Jetting

RISO Technologies' inkjet heads are highly regarded for their performance with high-viscosity inks.

Our ink-recirculation type CF1 has achieved a maximum jetting viscosity of 43.2 [mPa·s].

Wide operating window (OW)*1 and stable jetting peformance are secured.

-

*1:Operating window (OW): Range of driving voltage for stable jetting

-

※The viscosity shown above is the actual viscosity of ink at the moment of jetting.

-

※Inks shown above are inks that were actually tested. Performance varies depending on ink.

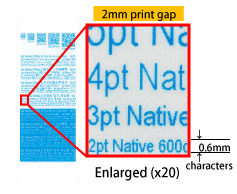

Print samples with high viscosity ink

<Printconditions>

Inkjet printhead: CF3R

Ink: UV ink

Viscosity: 30 [mPa・s]@25℃

The actual temperature during jetting: 25℃

Frequency: 13.8 kHz

Grayscale Level: 4 levels (3 drops)

Print gap: 2.0 mm

Resolution: 600 x 600 dpi

Linear Speed: 35 m/min

-

※High resolution printing is secured with high viscosity ink.

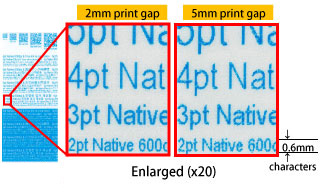

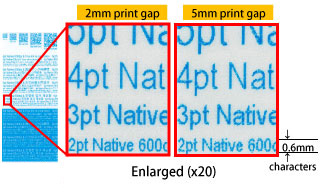

2. Wide Print Gap

RISO TECHNOLOGIES' inkjet heads offer good print quality with wider print gap.

Below are actual print samples with the print gap of 2.0mm and 5.0mm.

Print sample

<Printconditions>

Inkjet printhead: CF3R

Ink: UV ink

Viscosity: 30 [mPa・s]@25℃

The actual temperature during jetting: 25℃

Frequency: 13.8 kHz

Grayscale Level: 4 levels (3 drops)

Print gap: 2.0 / 5.0 mm

Resolution: 600 x 600 dpi

Linear Speed: 35 m/min

-

※The above are print samples actually tested with UV ink.

-

※Performance varies depending on ink.

RISO TECHNOLOGIES' unique and excellent technology of mechanical process and jetting control

minimizes deviation of jetting angles and achieves accurate dot placement even with wider print gap.

3. High Quality Printing

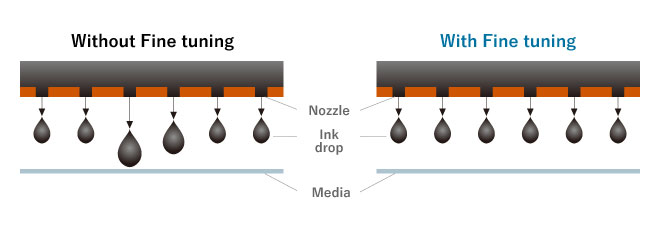

Drop volume adjustment on each nozzle

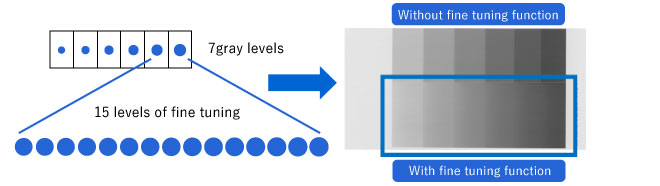

RISO TECHNOLOGIES' inkjet heads (CF3/CF3R) are capable of adjusting jetting volume of selected nozzles with its fine tuning fucntion.

The fine tuning function helps enhance print quality.

By adding 15 levels of the fine tuning function onto original 7 gray levels printing,it is possible to achieve up to 91 levels of gradation in total on each pixel.

The fine tuning function also helps reduce density variation which is visible at the borders between the inkjet heads mounted.

Original 7 gray levels + 15 levels of fine tuning = 91 levels of gradation

Fine tuning at the border of 2 inkjet heads

Excellent print quality

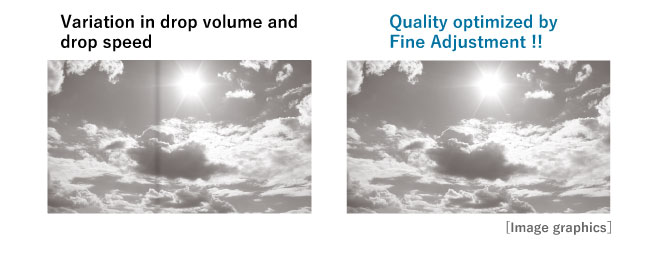

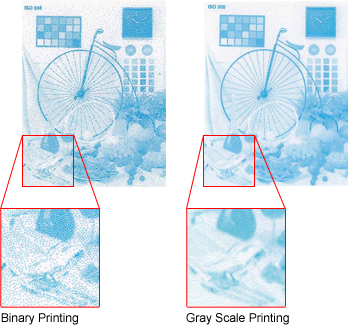

Smooth tone and less graininess

Multiple drop jetting technology*1 up to 7 drops creates 8 levels of density gradation within a single dot. This gives a smooth tone of image from light to dark with less graininess.

-

*1:A multi-value printing method that switches dot size by controlling the number of times ink is ejected.

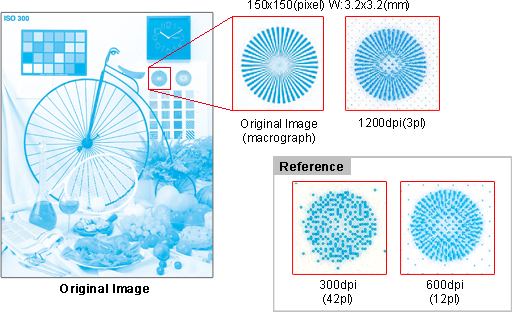

Printing with higher resolution

Fine art graphics can be reproduced with small drop jetting technology.

Native resolution of 600dpi enables a clear and sharp printing for as small as 2pt (0.6mm) characters.

<Printconditions>

Inkjet printhead: CF3R

Ink: UV ink

Viscosity: 30 [mPa・s]@25℃

The actual temperature during jetting: 25℃

Frequency: 13.8 kHz

Grayscale Level: 4 levels (3 drops)

Print gap: 2.0 / 5.0 mm

Resolution: 600 x 600 dpi

Linear Speed: 35 m/min