Inkjet Head "CF1B/CF1BL/CF1BXL"

The ultimate inkjet head for excellent jetting reliability with ink circulation

- Advantageous effects of ink circulation

- Auto and quick recovery of failing nozzles

- Stable print quality with uniform temperature

- Easy to fill ink

- Improve productivity

- Reduce running cost

- 636 nozzles with 300dpi nozzle density

- Within-a-dot gradation with multi-drop technology

- Excellent dot placement accuracy

Features

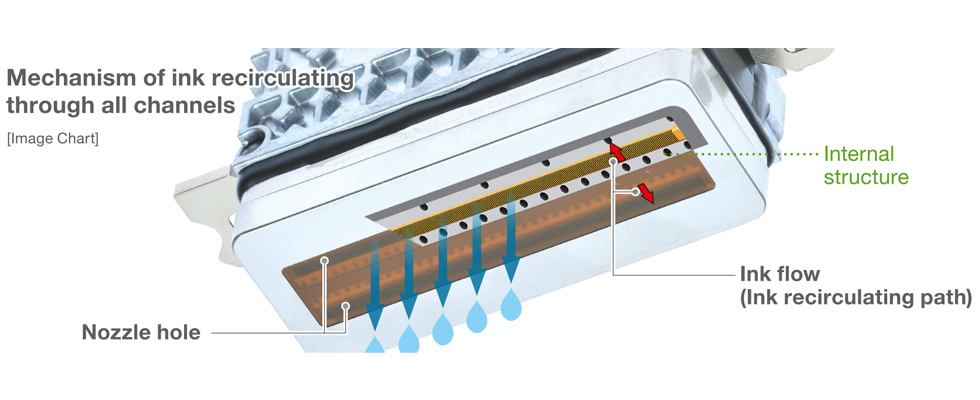

Ink circulation in the head prevents ink from staying in pressure chambers and keeps constant supply of ink.

With this feature, CF1B/CF1BL/CF1BXL offers a structual solution to the challenges of conventional inkjets.

CF1B/CF1BL/CF1BXL is an inkjet head that offers a long-awaited solution of enhancing jetting reliability, and its print quality well fits a wide range of application from transpromotional, label & packaging to sign & graphics.

In particular, CF1B/CF1BL/CF1BXL demonstrates its full merit for a singlepass printing where reliability is a top priority.

1. Structure

Ink is filled by way of ink inlet on the top and descend through the pipe to the foot where pressure chambers are located.

Ink spreads over to all the channels for printing.

Ink for printing is ejected by each nozzle and the rest of it is collected to the center to be ejected to outside by way of ink outlet pipe.

2. Advantageous merit of ink circulation

Alteration and sedimentation of ink in nozzle area can be avoided.

(1) Auto and quick recovery of failing nozzles

Failing nozzle may happen due to air bubbles or some other reasons. Circulation of ink removes those obstacles and the failing nozzle recovers almost instantly.

(2) Stable print quality with uniform temperature

Activity of head causes heat and may affect ink temperature.

Circulation of ink alleviates the influence of heat and helps stabilize jetting performance.

(3) Easy to fill ink

Conventional inkjet may have some problem starting printing job, which requires a lot of head maintenance work in order to get nozzle conditions in good shape. Use of CF1/CF1L/CF1XL minimizes the start-up trouble because its ink circulation feature keeps supplying ink preventing nozzles from being contaminated.

(4) Improve productivity

Not only the print speed but also the maintenance frequency greatly influences productivity. CF1/CF1L/CF1XL decreases the requirement of head maintenance.

(5) Reduce running cost

Ink circuration reduce the amount of waste ink resulting in reduction of the running cost.

These unique feature helps reducing ink consupmtion and CF1/CF1L/CF1XL gives more eco-friendly printing job.

Specifications

| CF1B | CF1BL | CF1BXL | |

|---|---|---|---|

| Print method | On-demand piezo technology | ||

| Ink recirculation structure | Ink recirculation through all channels | ||

| Print width | 53.7 mm | ||

| Number of nozzles | 636 | ||

| Nozzle resolution | 300 npi | ||

| Number of rows | 2 | ||

| Nozzle spacing (row-to-row distance) | 4.64 mm | ||

| Greyscale levels | 8 levels/0~7 drops | 4 levels/0,5,6,7 drops | 7 levels/0~6 drops |

| Drop volume | 6~42 pL | 57~80 pL | 36~180 pL |

| Frequency | 4.97 kHz/7 drops | 4.8 kHz/7 drops | 4.8 kHz/6 drops |

| Ink type | UV-curing & oil-based (consult us for compatibility assurance) | ||

| Built-in temperature sensor | Included | ||

| Head cooling method | Air-cooling | ||

| Size, weight | 94.1 mm (W) × 26 mm (D) × 79 mm (H), 161 g | ||

-

※Gradation levels and drop volumes depend upon the type of ink used. Maximum printing speed and linear frequency can be increased by reducing the number of drops per dot (dpd).

-

※Four different types of power supplies ( : 5 V, 39 V and two units of 14-31 V ) are required in order to drive head.

-

※The specifications above may be modified due to certain circumstances.

Product Inquiries / Download Brochure

Please feel free to contact us using the following links for inquiries concerning products or to request materials.