Direct Printing on Solid Object

Direct Printing on Solid Object

This field involves directly printing designs and information onto cylindrical or curved three-dimensional objects. Its applications span a wide range of products, including tumblers, bottles, industrial goods, sports equipment, cosmetic containers, and toys.

Features

Advantages of Inkjet Printing

- Direct printing eliminates the need of pasting labels, contributing to cost reduction.

- The plateless process enables support for small-volume printing of items such as memorabilia and limited editions.

- The use of high-adhesion UV inks improves durability.

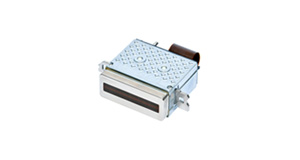

Features of RISO TECHNOLOGIES' Inkjet Heads

- High jetting power allows for high-quality printing by accurately landing ink on curved surfaces, even with wide distance between the head and the printing medium.

- Droplet volumes from a minimum of 3pL to a maximum of 180pL can be applied*1, allowing for use across a diverse range of applications.

- Ink recirculation resolves nozzle clogging, reducing head maintenance and replacement frequency, thereby significantly minimizing downtime.

- Two different colors of ink can be used with a single head*1, contributing to space savings in equipment, such as realizing smaller printers.

-

*1:Droplet volume and support for 2-color ink vary by product. Please refer to the product specifications for details.

Recommended Products

Related information

Product Inquiries / Download Brochure

Please feel free to contact us using the following links for inquiries concerning products or to request materials.